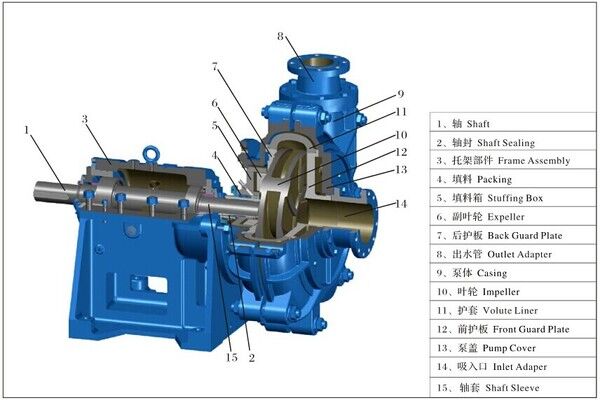

Impeller Surrounding the pump shaft the impeller energizes the slurry being moved. Pumps are the backbone of the process industry.

Differences Between Flush And Quench In Slurry Pump Seal Support Plans

The packing area of stuffing box is longer than expeller ring so it can contain more packing.

. Enters the two impellers to continue to pressurizethereby obtaining a higher lift. Describe slurry pumps slurry pumping and the various parameters required when selecting submersible slurry pumps using FLYPS. First of all slurry pumps should be designed for specific operating requirements.

Gravel pumps are designed for long life efficient operation and ease of maintenance for applications with large particle sizes. WEIR SLURRY PUMPING MANUAL iv1 Symbols used The terms slurry and mixture in this Manual are used interchangeably to describe a mix of any loose solids made up in any proportions and combinations of any particle sizes and any conveying liquidThe subscript w refers to densities and specific gravities of liquids mostly but not exclusively water. If playback doesnt begin shortly try restarting your device.

Open While slightly less efficient open impellers work well for slurry that contains a combination of fluids solids and. Videos you watch may be added to the TVs watch history and. Hydraulic Design of a Slurry Distribution Box 21.

They separate out oversized solids to create a slurry. Of course the number of rings of packing will depend on the design of the stuffing box and that will determine how to pack your pump. To reduce wear lower the pumps discharge pressure to the lowest point possible.

The licence agreement - signed by Sala was for an English design the Vac-seal slurry pump. 9 to 14 feet 27 to 43 m 10 to 15 feet 30 to 45 m 11 to 16 feet 33 to 48 m Adjustable in 6-inch 15 cm increments Bergkamp Spreader boxes are compatible with other brands of pavers Read more. In the early 60s Sala developed a new range of medium duty slurry pumps.

With many different pump types available selecting the right pump. Bergkamp Slurry Seal Spreader Box Specifically designed for Slurry Seal applications Available in these widths. International Gravel slurry pump.

Slurry pumps should be supplied together with mineral processing equipment thus providing for the first time a complete package. Features Design considerations. Hydraulic Institute 121-126-2005 deals with the design and operation of centrifugal slurry pumps.

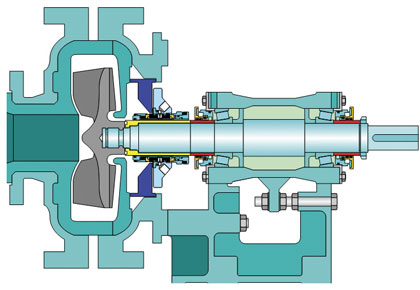

Gravel pumps have high-chrome wet ends with expeller or. A stuffing box separates the non-rotating parts from those that rotate. For these reasons soft compression packing is still favored as a means of sealing at the stuffing box.

Closed For those seeking high efficiency closed impellers are best. A standard pump may be able to handle the fluid but not as effectively as a properly sized slurry pump. To provide a deeper understanding of the calculations a manual calculation example is given in the appen-dix of the book.

Pump boxes or slurry pumps are used across the mining and oil and gas industries. Heres a rundown of slurry pump components and options. In keeping with the laws of thermodynamics fluids move from an area of high pressure to low and depending on the plant layout often require the assistance of a pump to achieve this.

When it comes to centrifugal slurry pump maintenance a stuffing box is the best option for time-sensitive issues that may arise. Slurry pumps are often subjected to severe shock loading and shaft whip due to the presence of solids and system upsets. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

Stuffi ng box pressure and keeping solids out of the gaps between the casing and impeller by centrifugal action. The preferred method for packing a slurry pump is the flush seal shown in Figure 13-5a. Distribution boxes are designed with a number of chambers and hydraulic controls to ensure thorough mixing of the incoming slurry streams and even distribution to each outlet of volumetric flow rate solids concentration and particle size while maintaining stable flow.

The Flowserve Titan Slurry pump is a true mill circuit slurry pump. Slurry Pump Handbook - 2009 Fifth Edition Electronic Version February 2009. Pumping slurries poses several challenges and problems but with proper engineering and equipment selection you can experience many years of worry-free operation.

In addition the radial feed design is adopted so that the pressure at the sealed box is equivalent to the impeller. They must also be able to pass large solids. If the particle size falls between 04 and 05 microns then you can attain the proper slurry concentration at around 40 below static settled.

It reflects the companys innovation and engineering expertise in hydraulic design materials science and manufacturing excellence. Slurry pump stuffing box is one of shaft seal parts in gland packing seal pumps where the packing is housed in. By maintaining the right level of slurry concentration consistency you can ensure the product moves through your system at a productive rate.

Wilfley Kpro K and HD slurry pumps are much more forgiving of improper inlet designs than any other pumps available. For the correct design and engineering of many slurry pump applications. In a process plant it is necessary to move material from one point to another.

Cavitation will quickly destroy the pump wearing away at the impeller and case causing bearing problems etc. This ensures your materials can be transported through pipelines to their end destination. Slurry pumps must have thicker vanes than water pumps to prevent wear.

They must be able to pump high-density abrasive slurries while maintaining reasonable wear life. If you are not sure about the type of slurry the choice of pump the design of the pipe system. Slurry pumps can be divided into horizontal slurry pumps and vertical slurry pumps according to the position of pump shaft and water level.

Clean water is injected into the stuffing box to flush solid particles away and to cool and lubricate the packing and shaft sleeve. Due to the increased thickness there will be fewer vanes otherwise the passages will be too narrow and will affect the performance of the pump. General Industries Mining Water Resources Primary Metals Pulp and Paper Power Generation.

Our pump boxes can be customized to handle any project regardless of size or scope. Compared with conventional water pumps the above requirements result in a larger pump that is less. David Brown Santasalo slurry pump gearboxes are used widely throughout the mining process and are designed to operate in tough duty cycles at the highest efficiency to deliver maximum performance.

New Pump Box For Sale By Savona Equipment

Types Of Mining Pumps Slurry Pump Gravel Dredge Pump

New Pump Box For Sale By Savona Equipment

The Business Case For Mechanical Seals In The Mining Industry Part 2 Of 2 Modern Pumping Today

0 comments

Post a Comment